Proteus becomes the world’s first manufactured non-cuttable material

Researchers from the UK’s Durham University and Germany’s Fraunhofer Institute claim they’ve come up with the world’s first manufactured non-cuttable material, just 15 percent the density of steel, which they say could make for indestructible bike locks and lightweight armor.

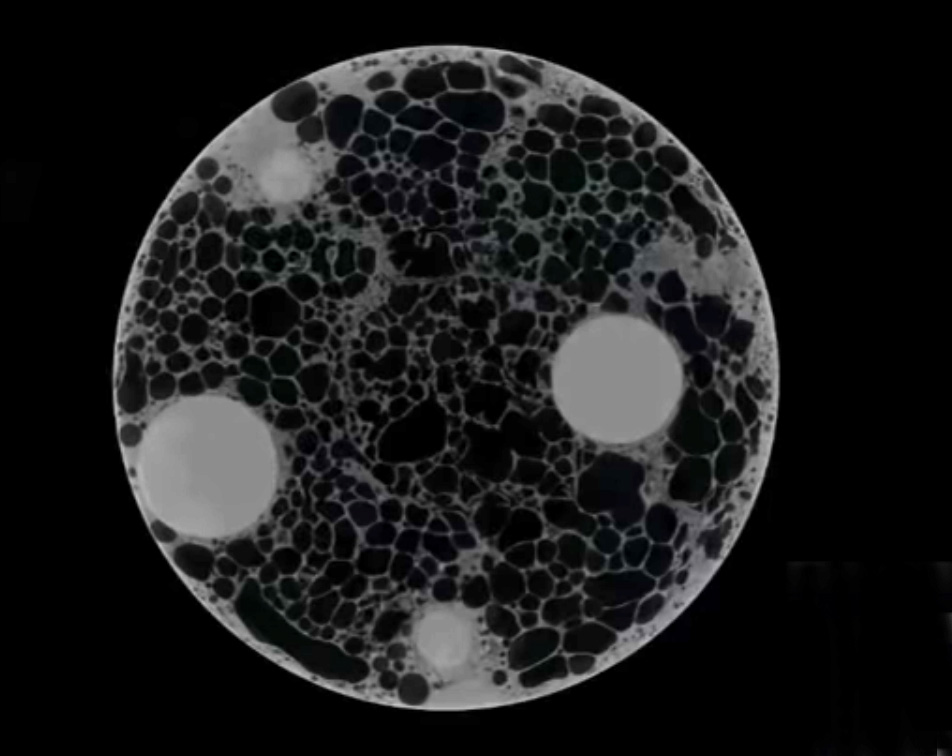

The material, named Proteus, uses ceramic spheres in a cellular aluminum structure to foil angle grinders, drills and the like by creating destructive vibrations that blunt any cutting tools used against it. The researchers took inspiration from the tough, cellular skin of grapefruit and the hard, fracture-resistant aragonite shells of molluscs in their creation of the Proteus design.

An angle grinder or drill bit will cut through the outer layer of a Proteus plate, but once it reaches the embedded ceramic spheres, the fun begins with vibrations that blunt the tool’s sharp edges, and then fine particles of ceramic dust begin filling up gaps in the matrix-like structure of the metal. These cause it to become even harder the faster you grind or drill „due to interatomic forces between the ceramic grains,“ and „the force and energy of the disc or the drill is turned back on itself, and it is weakened and destroyed by its own attack.“

The material is equally effective against high pressure water jet cutters – not that many bike thieves are hauling those around – since the spherical shape of the ceramic chunks tends to widen out the water jet, significantly slowing down its cutting speed.

Although not yet available commercially, Proteus may offer a wide range of potential applications, including use in high-security doors, elbow pads, and bike locks.

So far, however, the researchers have just made prototypes in two shapes and sizes: rectangular plates about 40 millimeters thick, and cylinders 60 millimeters in diameter.

In a blog post, Stefan Szyniszewski, the lead author of the new study, wrote that natural structures like those in Abalone shells and grapefruit peels inspired his team’s invention.

„Essentially cutting our material is like cutting through a jelly filled with nuggets“ said lead author Stefan Szyniszewski, Assistant Professor of Applied Mechanics, in Durham’s Department of Engineering. „If you get through the jelly you hit the nuggets and the material will vibrate in such a way that it destroys the cutting disc or drill bit.

„The ceramics embedded in this flexible material are also made of very fine particles which stiffen and resist the angle grinder or drill when you’re cutting at speed in the same way that a sandbag would resist and stop a bullet at high speed. This material could have lots of useful and exciting applications in the security and safety industries. In fact, we are not aware of any other manufactured non-cuttable material in existence as of now.“ Grapefruit peels have a similar structure, which can protect grapefruits from falls of up to 30 feet, according to the study.

Seashells and grapefruit peels are also relatively lightweight — as is Proteus. The material is 85% less dense than steel.

As well as bike locks and lightweight armor, the team feels Proteus has potential in protective equipment for people using cutting tools. It’s currently patent pending, and the research team is looking to partner with manufacturers to bring it onto the market.

The research was published in the journal Scientific Reports. Source: https://newatlas.com Photo: scitechdaily